Production and distribution

Production and distribution

Janssen produces and distributes high-quality treatments for patients in Belgium and throughout the world. Also, in this phase of the cycle do we innovate continuously. We do so on the basis of high-tech production processes and with a particular focus on digitalization, circular economy and renewable energy.

Our production facilities are located in Beerse, Geel and Olen. With our distribution centers in La Louvière and Courcelles, Belgium is the central hub for the distribution of all our activities in Europe. The Beerse site is even our worldwide hub for the distribution of clinical equipment.

Innovation in production

The second-largest pharmaceutical production site of the Janssen Supply Chain in Europe is located on our Janssen site in Beerse. Beerse is the center of the production of a wide range of products, such as products in liquid and semi-solid form, transdermal and sterile products. Due to the high production volumes, this is a high-volume site. Our Beerse site is also an important innovation hub thanks to a number of advanced processes. One example is our continuous production technology,1 which allows us to produce very large quantities in a much shorter time span.

The Janssen site in Geel is a high-tech, chemical production site that is responsible for no less than 60% of the total worldwide production of active pharmaceutical ingredients (APIs). All medicines consist of two core components: the active pharmaceutical ingredient and the excipients, the substances that help our body to absorb the medicines. At our site in Geel, 26 different types of active ingredients and three semi-finished medicines are produced, accounting for more than 200 tons of active pharmaceutical substances annually. In Geel, there is a particular focus on medicines for extremely complex syndromes, ranging from specific forms of HIV to certain types of prostate cancer.

In order to do this efficiently but also responsibly, we continue to invest continuously in the latest technologies and in educating and training our employees. Digital spray drying, an absolute world first for Belgium, was one of these innovative technologies that led us to receive the Factory of the Future Award from Action Plan Made Different in 2019.3

Birk Vanderweeën

Former Site Lead Geel Production Site

Continuous production technology

Continuous production technology

The campus in Beerse is a pioneer for new technologies in both drug development and production. One of the most striking improvements at the Beerse facility is illustrated by the investment of 21 million euros to implement a continuous production technology. This technology - considered revolutionary within the pharmaceutical sector - was developed in collaboration with Ghent University and Rutgers University. Traditionally, drugs are produced mainly by means of separate batch processes. By switching to a method of producing in one continuous process, our medicines are made available more quickly and we can respond more effectively when the demand for important new treatments increases. Thanks to this innovative technology, we are thus able to reduce production and testing cycle time, reduce waste and environmental impact, and generally lower the footprint of manufacturing facilities. We get this done without compromising on existing quality. This continuous production line attracts scientists with a specific focus on this technology and was voted 'Facility of the Year' in the 'process innovation' category by the International Society for Pharmaceutical Engineering (ISPE) in 2020.2

Spray drying

Spray drying

New drugs must treat increasingly complex disease patterns. As a result, the active molecules (APIs) - the active ingredients in those drugs - are also becoming increasingly complex and less soluble in water. However, this solubility is crucial for smooth absorption of the molecules by our bodies and thus for a better effect of the treatment. Thanks to digital spray drying, we mix the active ingredients with a solvent and a polymer, after which it is atomized in a spray drying chamber. The size and shape of the active particles can be better controlled thanks to this technology. Combined with sophisticated and accurate on-line measurements of the production process, we have made the uptake of these complex drugs by the human body much more efficient. The treatment of HIV is a nice example of this: patients were able to go from as many as 18 to only 2 tablets per day thanks to digital spray drying, a tremendous improvement that significantly increases the comfort and feasibility of treatment. This is also an important process innovation from a strategic point of view. With the site in Geel, we have a facility that is capable of producing many new medicines in Belgium in the future.

CAR-T

CAR-T

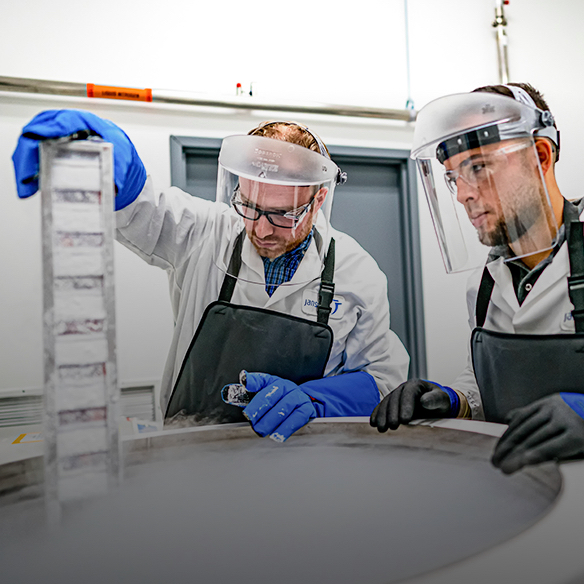

Janssen is building its first European production center for cell therapy in Belgium, a great first for our country.5 In collaboration with Legend Biotech, we are developing facilities in Ghent for the production and supply of CAR-T therapy for the treatment of cancer. CAR-T cell therapy is a personalized, therapeutic treatment for an individual patient that is based on collecting the patient's own blood cells. The patient's own immune cells are programmed, as it were, to recognize cancer cells and attack them after they re-enter the patient's body. The development and production of transformational therapies such as CAR-T cell therapy require great innovativeness and strong collaboration between industrial and academic partners, together with the competent authorities. This major investment and corresponding boost for the labor market follow from Belgium's pioneering role as a pharma valley in Europe, with the presence of the necessary knowledge, infrastructure, and local talent. With this personalized approach, we hope to eventually help more patients to overcome certain types of cancer.

Sustainable production

Because we use many different materials, we are constantly looking for ways to make our production processes more efficient and sustainable. For example, we are looking at how we can deal with our waste streams more consciously according to the principles of the circular economy and, where possible, even convert this waste back into raw materials. Together with InOpSys, a start-up that deals with the reduction of toxic waste, we have developed sustainable solutions for the purification of our process water. The 'Plant on a truck' project received the top prize at the 2018 Belgian Business Awards for the Environment.4 In this way, we are not only reducing our carbon footprint but also collaborating with innovative partners to promote the development of sustainable production processes further.

New innovative R&D platforms: CAR-T

Technological and scientific (r)evolution continues at a lightning pace. Personalized medicine, in which the patient receives a tailor-made therapy, is an important, new trend. These innovative treatments hold out the prospect of promising results for the patient, but they also follow a unique and differentiated production process. Janssen's CAR-T investment in Belgium demonstrates that our country can also play an important role in this area.

Distribution to Europe and the rest of the world

The distribution centers in Belgium play an important role in the European and worldwide distribution of medicines, vaccines, and medical instruments. These three centers - Beerse, La Louvière and Courcelles - are deliberately located in a relatively small geographical area. In fact, La Louvière and Courcelles are barely 20 kilometers apart. In the past, distribution was done from 15 local centers, spread all over Europe. By bringing the distribution of all medicines and vaccines produced in Europe together in one place, we are improving the logistics process. Belgium is thus the European distribution center for treatments and medical instruments available on the market. With regard to the material used in clinical studies - i.e., for a registration - we are even the global 'distribution hub'.

From Belgium, more than 10,000 hospitals, wholesalers and pharmacies in several Western European countries are supplied with 24-hour distribution, totaling approximately 30,000 orders per month. The production and shipping of medicines are done according to the highest quality standards. Indeed, we have the ambition to be 'best in class' in our sector. Therefore, we work closely with our production facilities to guarantee '1 order, 1 delivery, 1 invoice' in order to provide the best possible service to all those who wish to use our medicines, vaccines and medical instruments.

COVID-19: Additional storage capacity for the COVID-19 vaccine

COVID-19: Additional storage capacity for the COVID-19 vaccine

Our Beerse site has numerous crucial functions. For example, it is not only an R&D and 'production hub', but also an important storage location within our global supply chain network. Among other things, the Ebola vaccine is stored in Beerse. This is a specialized refrigeration infrastructure, as vaccines are stored at temperatures ranging from -20°C to even -60°C. After the outbreak of the corona pandemic, it quickly became clear that the Beerse hub would play a crucial role in the distribution of our COVID-19 vaccine, primarily within Europe but also in other parts of the world, due to its location, existing facilities, and highly trained personnel. Because the demand for vaccines is so great, a completely new warehouse was built in just seven months. This would not have been possible without the smooth cooperation with the competent authorities. This has allowed the storage capacity to be increased significantly and in an innovative way. This is what we call a 'flexible refrigerated warehouse', where one can switch between a frozen temperature and a refrigerated temperature at the same location with a short turnaround time. This is important in order to be able to deploy the vaccine as quickly and efficiently as possible.

COVID-19: Stock During COVID-19

COVID-19: Stock During COVID-19

Janssen made every effort immediately after the outbreak of the corona pandemic to avoid drug shortages in the disrupted world market. This concerned a number of our essential medicines that are necessary for the treatment of hospital patients in intensive care units. By consulting with the authorities and carefully monitoring the stock levels, we were able to ensure sufficient supplies and distribute them despite the high demand.

COVID-19: Production of disinfectant hand fluid in Geel

COVID-19: Production of disinfectant hand fluid in Geel

The rapid spread of the coronavirus in March 2020 led to a sharp increase in the demand for medical supplies. In Belgium, for example, there was an acute need for 20,000 liters of disinfectant hand gel in the short term in order to avoid an imminent shortage in healthcare. Although Janssen does not produce any disinfectant hand fluids itself, the decision was taken to start up a new production process at the chemical production site in Geel within a record time of less than two weeks. The rapid production was possible thanks to a close cooperation with the federal government, Zorgnet-Icuro, the university hospitals UZ Leuven and UZ Gent, and the companies Filliers and Tereos.

SDG 7: Sustainable and affordable energy

SDG 7: Sustainable and affordable energy

Without energy, we cannot do research and make medicines. Much of the world's energy is still derived from coal, oil, and gas. So, where we get our energy from has a big impact and we deal with that in a conscious way. With our 'Energy and Water Team' project we identify energy and water saving measures that will help us to make our energy consumption more sustainable. In Belgium, we are working hard to have the campus run entirely on renewable energy by 2050. We are investing in green energy sources here, for example through our own wind turbine in Geel. In 2019, with support from the Flemish Government, we also started a geothermal project on our site in Beerse, the first private initiative of this kind in our country. We are drilling for geothermal energy at a depth of no less than 2,700 meters on our campus site. By connecting the hot water at 85°C from the ground to our heat network, we will be able to use it to heat and operate our buildings. In this way, we are able to reduce our CO2 emissions by as much as 20%. By making smart use of natural energy sources and sharing our acquired knowledge with others, we are dealing with our planet in a sustainable way and contributing to the Health Goals with regard to renewable energy.

Sources

https://ispe.org/facility-year-awards/winners/2020/process-innovation

https://www.janssen.com/belgium/janssen-invests-european-production-site-cell-therapy-belgium